Benefits & Features

BUSHPEX Crimp-On PEX Plumbing System:

- Manufactured, distributed and supported by Elson.

- 25 year product warranty against product defect when

installed according to detailed requirements. - Product manufactured by Elson to relevant Australian

Standards by our ISO 9001 approved manufacturing

facility with all Watermark Certification by SAI Global. - Cost effective alternative to other systems.

- Fast and easy to install.

- BUSHPEX Crimp-On tools & jaws can be used for both

BHSHPEX Crimp-On water and BUSHPEX Crimp Gas PEX-AL

systems. - BUSHPEX pipe properties:

- – Low water flow noise.

- – Strong impact resistance.

- – Heat and corrosion resistant.

- – Light weight and easy to install.

- – Significantly reduces water hammer.

- – High Pressure rating 2000kPa @ 20C.

- – Smooth inner core to reduce pressure loss.

- – Low levels of thermal conductivity and expansion.

- – Coils provide fast installation, less joints, save time,

save costs. - – Available in Black for hot and cold water, Red specifically for hot water, Green for rainwater harvesting and Lilac for recycled water in sizes

16mm, 20mm and 25mm. - – Same pipe is compatible with two BUSHPEX

jointing systems – Crimp-On, Pull-On

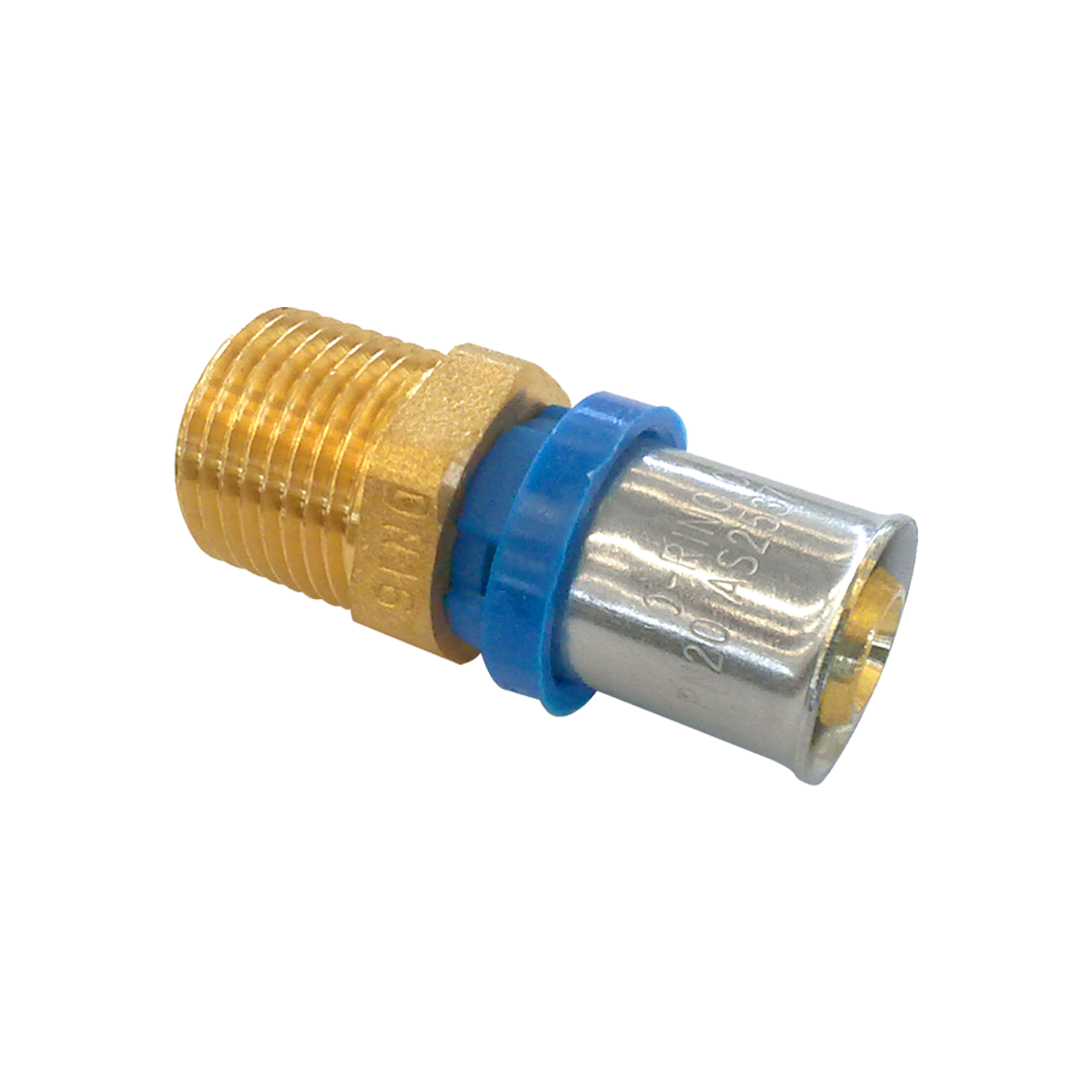

- BUSHPEX Crimp Fitting properties:

- – Double “O” ring, double indentation Crimp jointing system is the most secure Crimp jointing system on the market that is preferred internationally.

- – Long entry stainless steel crimp sleeves that don’t fall off the fitting.

- – Four easy to inspect witness holes to confirm complete insertion of pipe into fitting.

- – Blue retaining ring signifies “water” and also locates the Battery Tool Jaw.

- – German manufactured Battery Tools and Jaws developped, tested and approved for BUSHPEX.

- – DR Brass quality fittings – strictly controlled according to ISO 9001 systems.

- National support network for training, technical information and tool service.

Pipe & Fitting Protection and Care

BUSHPEX pipe and Crimp-on fittings must be protected from damage through all stages of the process from transport to storage and installation in accordance with AS/NZS 3500. Provision for pipe and fitting protection therefore includes but is not limited to the following:

- Care must be taken to keep the pipe and fittings free of grit, dirt, dust and any foreign matter. All blue retaining rings must be securely seated onto the fitting along with the stainless steel crimp sleeve and dual “O” rings.

- Pipe must be protected from physical damage. Including cuts, abrasions, dents, kinks, tears, holes, etc.

- Pipes, either black, red, green or lilac, are not to be installed in direct sunlight.

- Pipe must be protected from long term or permanent U.V. exposure, by way of lagging, enclosing in a conduit etc.

- Pipe and fittings must be protected from excessive heat or burning, chemical / solvent attack, animal or rodent attack, machinery damage, other external threats, etc.

- Pipe must never be installed where it could be exposed to a naked flame. PE-Xa Pipe has the potential to ignite and continue to burn after the source of the flame is extinguished. In accordance with AS/NZS 3500, all plastic pipe for water supply must be protected from excessive ambient heat.

- Chemical or corrosive environments.

- – Pipe must be protected.

- – Fittings must be wrapped and protected. This

includes all underground installations for all fittings.

- Pipe support and clipping, both vertically and horizontally is required to ensure conformance for vibration, excessive tension, torsion or compressive stresses on fittings and pipe. Refer to Pipe Specification Chart for spacing.

- Pipe penetrations through timber and steel frames and concrete sections must conform and may require protection using grommets, fire collars, sleeving or wrapping. Holes, notches and cut-outs must be accurately drilled “in-line” to allow movement for expansion and contraction of the pipe and fittings so joints are not exposed to excessive stress. Refer to Pipe Specification Chart for timber frame cut-out limitations.

- Pipe expansion and contraction needs to be accommodated during installation to allow for movement due to thermal Linear Expansion. Failure to do so may exceed the torsional pull-out allowances on fittings resulting in leakage. Refer to the Pipe Specification Chart for the Thermal Expansion Co-efficient.

- BUSHPEX pipe is flexible but requires care when bending to avoid kinks or other permanent deformation that may restrict flow or put undue pressure on joints. If the pipe is kinked or damaged in any way it must be cut-out

and replaced. BUSHPEX Crimp-On elbows are recommended for tight bends. Refer to the Pipe Specification Chart for minimum bending radius and tools for bending. - Connecting Barb soldered connection require special attention. Prior to crimping and soldering, remove/ dismantle the blue retaining ring, stainless steel crimp ring and two “O” rings. Solder the brass connection barb and allow to cool before re-assembly. When assembling the fittings ensure the blue plastic retainer ring, the two “O” rings and stainless sleeve are installed correctly. Refer to the picture on page 7 of this brochure for assembly detail.

- In accordance with AS/NZS 3500 regions with extreme hot or cold temperatures require appropriate product selection and/or insulation for protection and compliance. Consideration should also be given to insulating the pipe for energy efficiency as well as the prevention of condensation which can occur in hot and cold lines.

Handling & Installation

Underground Installation

NOTE: It is a requirement to pressure test the pipe and fittings in accordance with AS/NZS 3500 prior to burying or concealing the BUSHPEX Plumbing System. Underground installation of BUSHPEX Crimp-On pipe and fittings must be in accordance with AS/NZS 3500 including but not limited to the following :

- Minimum buried depth required by standards.

- Minimum pipe separation distance.

- Wrapping and protection.

- Conduit sleeving through slab penetration.

- Underground Piping installation recommended with no joints.

- Concrete slab piping must be continuous with no joints.

BUSHPEX Crimp-On Tools

BUSHPEX Crimp-On Tools are specifically designed to be used with the BUSHPEX Crimp-On PEX Pipe and fitting System and must not be used with other systems. BUSHPEX Crimp-On Tools are manufactured to precise specifications and require care and regular maintenance to ensure accurate and consistent operation. The cleaning of tools and jaws is recommended after each use. Always keep your tools and jaws free of dirt, dust, moisture and corrosion. Lubricate jaws regularly to provide smooth operation.

It is essential for all installers to read and recognise the operational requirements of the tools along with the Jointing Procedures and safety recommendations included in this manual and the Tool Instruction Manual.

Rounding the pipe with the BUSHPEX approved Manual or battery drill calibrating tool adaptor is an installation requirement which saves time and effort with a smooth insertion over the “O” ring.

It is recommended to incorporate a checking procedure to ensure that each joint has been correctly crimped by testing every joint with a crimp gauge and marking as complete.

IMPORTANT – Please consult the Jointing Procedure included in this manual. This Guide procedure is a product installation requirement.

Ring Mains/Recirculating Hot Water Systems.

If not configured correctly, the entire plumbing system

may have a dramatically reduced service life.

Recirculating Hot Water Systems or Ring Mains minimise the time it takes to get hot water to reach an appliance or outlet. It is also known that the continuous flow of water with exposure to high temperatures and high velocity makes this a very extreme and demanding application, whether using copper, Pex, or other piping materials.

To ensure system service life is maximised and to cater for the performance tolerances of heat sources, the following installation and water quality guidelines must be followed on any circulating hot water systems using Bushpex plumbing system in order to maintain the product warranty.

- Maximum pressure within the ring mains / recirculating hot water systems must be limited 500kPa (as per AS/ NZS 3500) .

- Maximum water temperature must not exceed 60°C.

- The pipe work design and recirculating pumps must be sized to limit the water velocity to the requirement of AS/NZS 3500 for non-metallic piping. Where copper pipe is part of the installation, the velocity restrictions for this material is extremely critical and must not be exceeded.

- A timer controlled recirculation pump must be used with a maximum circulation time of 12 hours per 24- hour period. All pipe work should be insulated and the recirculating pump must be thermostatically controlled, to further reduce stress on the system and minimise energy consumption.

- The system layout of pipework and fittings should be designed with long wide sweeping pipe bends with limited use of fittings.

- Water quality – Australian city potable water reticulation systems as defined in the Australian Drinking Water Guidelines.

ELECTROCUTION WARNING!

The potential threat of electrocution and death must be recognised if an earth line is disconnected by cutting metal pipes. ALWAYS check with a licenced electrician prior to proceeding.

Jointing Instruction

System Testing & Certification

Pipe and joint system testing must be carried out in accordance with AS/NZS 3500 and any other applicable local authority requirements prior to burying or concealing the BUSHPEX Crimp-On Plumbing System.

It is the responsibility of the Licenced Installer to ensure that all joints and fittings are inspected, tested and checked for leaks to ensure safety and compliance.

It is recommended to incorporate a checking procedure to ensure that each joint has been correctly crimped by testing every joint with a crimp gauge and marking as complete.

Warranty

The BUSHPEX Crimp-On Plumbing System carries a 25 year product warranty which covers product manufacturing faults and defects. This warranty only applies under the following requirements:

- The system must have been installed by a licenced Plumber.

- Proof of installation by a licenced Plumber is required.

- Proof of purchase is required.

- Installation must be in accordance with AS/NZS 3500.

- Installation must be in accordance with any other relevant

and applicable local authority codes which may take

precedence. - Installation must be in accordance with established

installation practices. - Installation must be in accordance with the jointing

procedures included in this manual. - Installation must only ever involve the use of the same

approved BUSHPEX Pipe (watermark certificate

WMKA 21274), BUSHPEX Crimp-On fittings (watermark certificate WMKA 21276) and BUSHPEX approved tooling.

Elson Australasia Pty Ltd undertakes to repair or replace product which is found to be faulty or defective in workmanship or manufacture according to the warranty conditions. The benefits provided to the consumer by this warranty are in addition to other rights and remedies available to the consumer under the law.

To make a warranty claim please contact Elson Australasia Pty Ltd with your contact details, proof of purchase and Licenced Installers documentation details. If the product has not been installed please contact the place of purchase and return. If there is a problem returning the product please contact Elson Australasia Pty Ltd. To make a claim under warranty you must abide by the warranty conditions.

Elson Australasia Pty Ltd

ABN: 45 059 613 991

38 Eddie Road, Minchinbury, 2770.

Phone: 02 9625 7899 Fax: 02 9625 7855

Email: sales@elson.net.au

Our products come with guarantees that cannot be excluded under the Australian Consumer Law. You

are entitled to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

To the extent of the Law, Elson shall not be liable for

any consequential loss or damage of any kind caused

by any product faulty or defective in workmanship or manufacture.

FAQ’s

Can BUSHPEX pipe be installed under a slab?

YES – with the following requirements

- Installation in accordance with AS/NZS 3500.

- Installed within BUSHPEX corrugated sleeve conduit.

- Must be sleeved when penetrating through a slab.

- Installed in a single continuous length without fittings.

Do I need to inspect the pipe end prior to crimping?

YES, always inspect the pipe and ensure it is cut square, has been “rounded & deburred”, has no rough edges and the internal and external pipe is undamaged prior to crimping.

How can I tell if the pipe has been pushed into the fitting properly?

Inspect the fitting to ensure the pipe is visible through all 4 witness openings.

If the battery Crimp-On Tool does not fully compress what must I do?

- Release the trigger and jaws by actuating the retract slide.

- Recharge the battery or replace with charged battery.

- Crimp the joint a second time and check with the crimp

- gauge.

If the jaws of the Manual Crimp Tool do not align when closed what must I do?

Adjust the jaws and test until the jaws align and have no gap. Follow the process described in the section, “jointing procedures - Tool adjustment”.

Can braze-on adaptors be installed after crimping BUSHPEX Pipe?

NO – Brazing must only ever be done prior to the crimping of the BUSHPEX pipe to the fittings with “O” rings, blue plastic retaining ring and Stainless Steel Sleeve removed. Other option? Use BUSHPEX PRESS fittings from copper to BUSHPEX Crimp-On.

Can BUSHPEX pipe and fittings be used to connect solar panels to the storage tank?

NO – Australian Standards do NOT allow PE-X Pipe to be used on the flow or return lines between solar panels and solar storage vessels.

Can BUSHPEX pipe be used for underground cold water service applications?

YES – when installed in accordance with AS/NZS 3500 requirements.

Do I need to “calibrate” the pipe prior to every crimp joint?

YES – this is a requirement for every joint - ensure that the reaming / calibrating tool suits BUSHPEX Crimp-On Pex Pipe.

Do I need to check every crimp joint has been compressed properly?

YES – you should check every crimp joint has been compressed properly by testing with the crimp gauge.

Do I need to inspect the crimp fitting prior to every crimp joint?

YES – you should visually inspect each fitting to ensure it is free of any dirt and grit, has both ”0” rings intact, the stainless crimp sleeve is properly located and all parts are undamaged - clean / replace / discard as required.

Is there anything I need to do before using a Manual Crimp Tool?

YES - follow all of these important steps below:

- Ensure that the tool is comatible with BUSHPEX PEX pipe and BUSHPEX Crimp-On Fittings.

- Ensure the tool is good working order.

- Ensure that the jaws align and have no gap when closed.

- Ensure that the jaws are clean, free of defects and debris.

- Refer to Jointing Procedure in this manual for correct method.

Is there anything I need to do before using the approved battery Crimp Tool?

YES – follow all of these important steps below:

- Ensure that the tool is compatible with BUSHPEX Pex Pipe and BUSHPEX Crimp-On fittings.

- Read and recognise the instructions contained in the manual.

- Ensure the correct jaws match the tool, the pipe and the fittings.

- Inspect the tool to ensure if functions properly.

- Inspect the jaws to ensure they’re clean, dry, free of dirt.